At Consolis, we know how to make a difference – for our employees, for the planet and for local communities. We do this by decreasing our environmental footprint, improving resource-efficiency throughout the value chain and by offering a diverse, equal and inclusive workplace where people get the opportunity to grow. We apply the highest ethical standards to our operations. And when starting a new project, we do not just provide high-quality products. As a community builder, it is also our job to improve the quality of life in the communities where we operate.

Our market-leading position entails a big responsibility to push ourselves and our industry forward. And with our products, we can significantly reduce the environmental footprint of construction.

We have decided to support the Ten Principles of UN Global Compact — including the adoption of a precautionary approach to environmental challenges. We have committed ourselves to support the UN Sustainable Development Goals, which guide our approach as a business.

We have also committed to set targets in line with Science Based Targets initiative. With deeds, not words we take this step in turning our business strategy into action, in line with the latest climate science. This enables us to contribute even further to developing sustainable buildings and societies.

Well-built for well-being for now and for future generations.

Green Spine Line®

A solid spine is what gives strength and stability.

It’s also a carrier of determination and courage. To take the lead in reducing the building and construction industry’s environmental footprint, you will need both.

This is why we launched Consolis Green Spine Line® – our certified precast solutions with at least 15% lower CO2 emission than local industry standards.

Reducing the climate impact is one of the most important challenges we, and the whole building material industry are facing. At Consolis, we are determined to take the lead in the sustainable transformation of our industry, with the goal of being climate neutral by year 2050.

Environment

Consolis’ ambition is to take our customers and our industry on a sustainable and circular journey, towards climate-neutral products and production.

The key to reduce the CO2 impact of concrete products is smart design and decreasing the CO2 intensity of the raw materials.

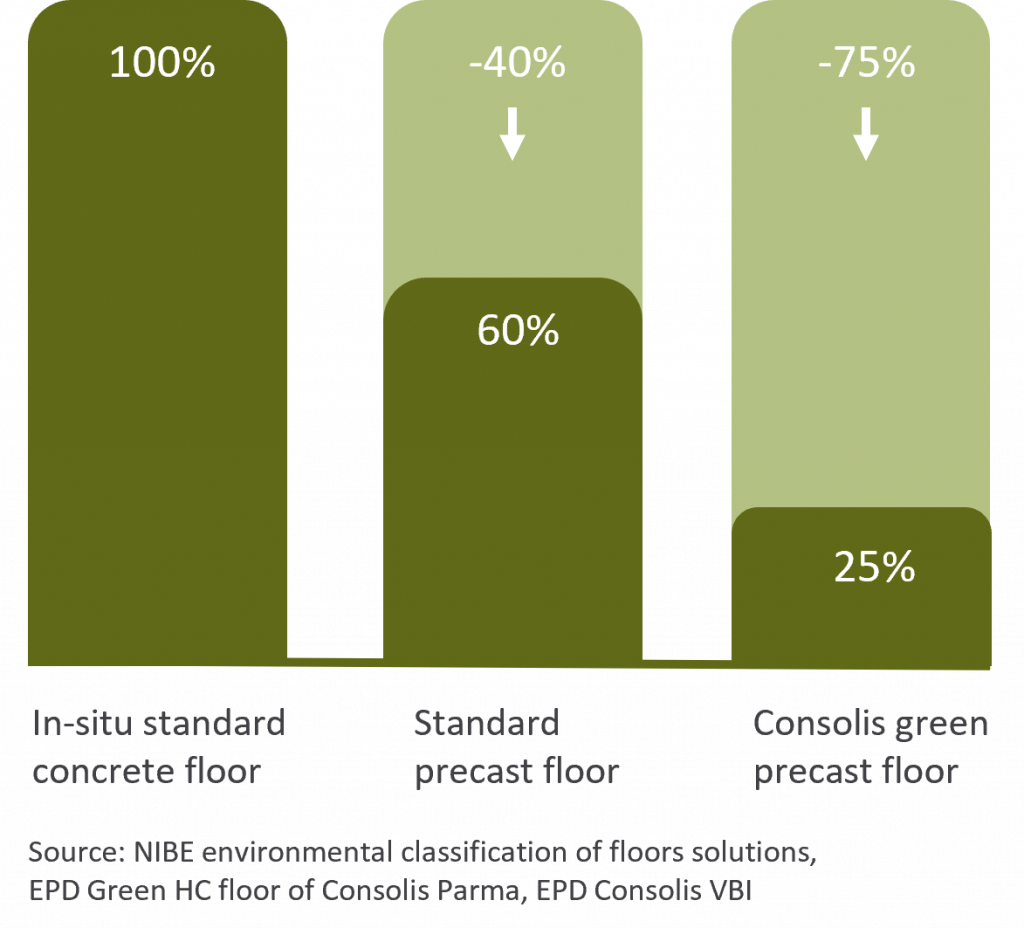

Precast concrete is more resource efficient, and lowers CO2 emissions by 40 percent compared to traditional in-situ solutions. As an example, hollowcore floors use about 40 percent less concrete and 50 percent less steel than cast in-situ or semi-filigree floors – reducing carbon footprint by almost half.

And when produced with secondary cementitious materials (SCM) or other alternative binders, hollow core solutions can even reduce carbon emissions by up to more than 75 percent, compared to other building solutions.

Together with our partners, we continuously develop new and more sustainable products that help us reach the industry targets of reducing the environmental impact by 50 percent in 5 years. By 2030, climate-neutral concrete will enter the market and our longer-term vision is that all concrete should be climate-neutral.

While continuously developing new, greener materials, Consolis is also committed to increasing circularity. By recycling and reusing concrete, we can reduce the use of virgin materials and further reduce our environmental impact.

Environmental engagements

Consolis’ international engagements and commitments ensure that our environmental efforts have real effect and take us in the right direction. As our annual report documents, un-locking the environmental challenges in the industry is a strategic priority and a key pillar in Consolis’ strategy.

Environmental Product Declarations

To push ourselves and our industry forward, our environmental efforts are measured with Environmental Product Declarations (EPDs).

Environmental data is consolidated and reported continuously, in terms of raw materials use (cement, secondary cementitious materials, steel, and water), energy use (electricity, district heating, natural gas, oil etc.), waste (concrete, steel) and transport of our products.

ISO14001

87 percent of Consolis’ precast concrete products are produced in 36 plants that have a certified Environmental Management System (ISO 14001) in place.

An additional seven percent are produced in plants with an Environmental Management System in place, but that are not yet certified.

CODE Standard Environment

Most of our production sites apply Consolis’ own lean-based concept, ensuring that Consolis’ high standards are followed throughout production.

The CODE covers environmental aspects, leadership commitment, legal compliance, regulatory permits etc., and allows for cross-border sharing of best-practices and continuous improvements.

Environment related projects

Consolis collaborates with suppliers, architects, designers, engineers and end-customers to reduce the environmental footprint of our industry.

We initiate our own environmental projects and engage in EU projects to push boundaries and develop low climate impact precast solutions.

- EU H2020 ReCreate

- Tekla BIM Award

EU H2020 ReCreate project - Low Carbon Circular Industries

ReCreate is an EU-funded project that investigates how used precast concrete elements can be profitably dismantled without being damaged for reuse in new buildings.

The four-year project has been awarded € 12.5 million by Horizon 2020, the EU’s framework program for research and innovation.

As a participant in the project, Consolis will explore, evaluate and develop technical solutions for recycling and reprocessing used precast elements into new productions.

Tekla-BIM-Award for a new wastewater treatment plant

Digital technology is an important competitive advantage for Consolis. One of our most important technologies is BIM (Building Information Modeling), the digital representation of all the physical and functional characteristics of a building or facility.

With BIM, we optimize design and sustainability, simplify planning, define construction costs, and calculate the Total Cost of Ownership for our clients. In 2020, the new 70,000 m3 Blominmäki wastewater treatment plant in Finland received international recognition at the Tekla Global BIM Awards 2020, as the winner of the category “Best Industrial Project”.

With more than 2,000 concrete elements delivered by Consolis, the award recognizes our visionary use of technology and our ability to enable a smarter and more efficient design and construction process. When completed in 2022, the plant will be the most productive in the Nordics, removing up to 99 percent of phosphorus from the water, and treating the wastewater of 400,000 inhabitants in Finland.

Health and safety

The well-being of our employees, partners, customers or anyone visiting our production sites is our top priority, and we aim for zero accidents. Our health and safety work originates with Executive Management and is implemented by all our local businesses.

We proactively build risk awareness, prevent work-related incidents, share best practices and continuously increase control of the work environment. Our “don’t walk by” principle calls upon everyone to constantly be vigilant, for their safety and for the safety of others.

In addition to local health & safety audits, Consolis carries out an annual safety week across all business entities, allowing for all employees to engage with all dimensions of safety.

People and work environment

At Consolis, we aim for engaged and motivated employees with equal opportunities. With operations in 17 countries, Consolis acknowledges the value of diversity in a broad perspective. We believe that in order to be successful, we need to ensure a welcoming work environment where it is not who you are or where you come from that counts, but what you bring in terms of knowledge and experience. Diversity and equality are prioritized areas throughout the organization, and encompass everything from recruitment processes to employee dialogues and career development.

We are committed to being an attractive employer with safe, collaborative workplaces and environments where people and teams reach great results. To continuously grow our expertise, Consolis provides leadership and employee training both locally and at group level. These initiatives range from people and management training to technical and operational development.

Business ethics

With operations in 17 countries, we are committed to running our business according to high ethical standards and with transparency – no matter where we operate. This is as important for our customers, shareholders and other stakeholders, as it is for management and our current and future employees. Our business and all our operations are guided by Consolis’ Code of Conduct, which covers Human Rights and Employment, Health and Safety, Business Ethics and Environment, and it includes important principles for anti-bribery and money laundering.

The Code builds on our core values and sustainability commitments, international and national legislation, and it supports the United Nations’ Global Compact as well as other international ethical guidelines. The requirements of our Code of Conduct apply to all Consolis employees, leaders and board members, in all markets and at all times.

Whistle blowing system

Employees, customers, suppliers, partners, investors and any other stakeholders of Consolis are encouraged to report any conduct that they believe is in breach of Consolis Code of Conduct, Suppliers Code of Conduct, policies or applicable laws and regulations. Any potential issues shall be reported via Consolis whistle blowing tool, a service that is provided by a third party.